Popit Recycling is pioneering a cost-effective, closed-loop recycling system for the dairy industry. Founded in 2024, the company has developed an innovative takeback recycling solution to help milk companies meet their sustainability targets while reducing the high cost of recycled high-density polyethylene (HDPE) plastic. By transforming how milk bottles are collected, processed, and reused, Popit Recycling is setting a new standard for sustainable packaging solutions.

Based in Australia, Popit Recycling operates at the forefront of sustainable waste management, working closely with leading dairy producers.

Their takeback recycling model and cutting-edge machine significantly reduce recycling costs, making sustainable packaging more accessible.

As a startup disrupting the recycling industry, Popit is leading the charge in providing affordable, high-quality recycled HDPE solutions.

The cost of recycled HDPE plastic is a major challenge for the dairy industry, with prices currently 40% higher than virgin plastic. Recognising this barrier, Popit Recycling was founded to provide milk companies with a low-cost alternative. Instead of relying on traditional commingled recycling bins, Popit’s approach sees milk companies take back empty bottles directly from customers. These bottles are processed on-site using Popit’s revolutionary machine, producing high-quality recycled material at a fraction of the usual cost.

This streamlined process not only ensures a reliable source of recycled HDPE but also lowers collection and contamination costs. With partnerships like Procal and Martogg, Popit Recycling is closing the loop on plastic waste, making it easier and more affordable for dairy companies to meet their sustainability goals.

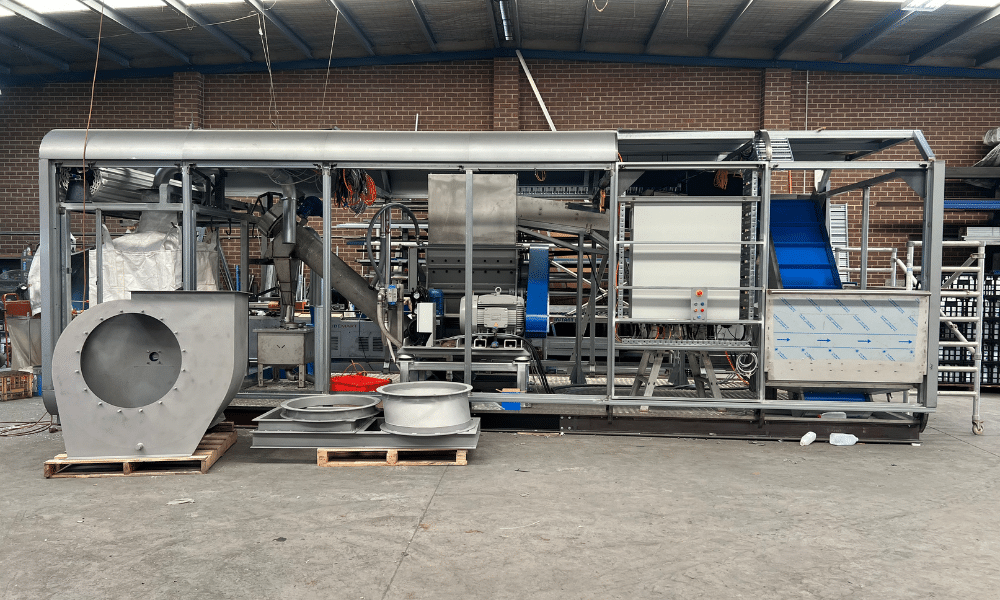

Popit Recycling provides numerous advantages for milk companies and business customers. The takeback recycling system bypasses traditional commingled bins, reducing collection and recovery costs while minimising contamination. Business customers benefit from lower recycling bin costs, while milk companies save money by recovering more of their milk crates. Additionally, Popit’s innovative machine is over 20 times cheaper and five times smaller than conventional hot-washed flake systems, making sustainable recycling more accessible and cost-effective.

Popit Recycling’s cutting-edge machine is redefining on-site plastic processing, making it over 20 times cheaper and 5 times smaller than conventional hot-washed flake systems. The machine operates in two stages:

AI-powered sorting:

The machine’s vision AI system detects and removes any non-recyclable rubbish mixed with returned milk and cream bottles.

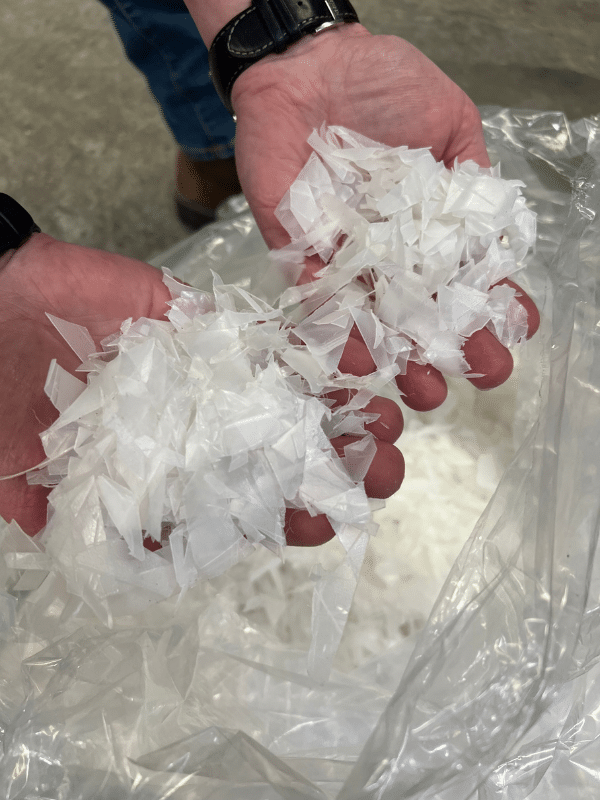

Flake creation:

The bottles are rinsed and shredded into small flakes, similar to confetti.

Drying process:

The flakes are carefully dried to prevent contamination.

Packaging:

The clean flakes are packed into bulk bags for transport.

These initial flakes from 1A are used to manufacture irrigation pipes, repurposing plastic waste into valuable products.

These hot-washed, colour-sorted flakes from 1B are transformed into FDA-compliant recycled HDPE pellets by manufacturing partner Martogg. These pellets are then used to produce new milk bottles at Procal’s on-site bottling facility, ensuring a fully circular recycling system.

Popit Recycling isn’t stopping here. They’re actively developing new features based on customer feedback, including:

Automated bottle loading to streamline the recycling process.

Full bottle processing to handle expired milk bottles from supermarkets.

By continuously innovating and refining their processes, Popit Recycling is leading the way in making sustainable packaging a practical and cost-effective reality for the dairy industry.

Subscribe today to keep up to date with all things renewable, get the latest news, and receive fantastic deals.

Serving Canberra, ACT; Sydney, NSW; Melbourne, Victoria; Adelaide, SA; Perth, WA; Brisbane, Queensland; Hobart, Tasmania; most Australian cities and regional areas including Gold Coast, QLD and Newcastle, NSW.

© 2005-2024 Energy Matters | ACN: 632 317 545 | ABN: 41 632 317 545