Hot topics rarely come hotter than this. As Australia and many other countries race towards cleaner, renewable energy, questions have arisen about the use of ‘dirty nickel.’ A range of raw and synthetic materials is used in manufacturing batteries, solar panels, inverters, and other renewable energy technologies. From aluminium to lithium-ion, cobalt to silicon, the components that drive our transition to net zero must be scrutinised. The path to net zero must not leave marginalised communities or a degraded environment in its wake.

In this blog, we’ll explore the use of ‘dirty nickel’ across the renewables industry, including in electric vehicle manufacturing.

What is ‘Dirty Nickel’?

To get to the nitty gritty of ‘dirty’ nickel, we first need to understand what nickel is and how it is used.

What is nickel?

Nickel is a silvery-white metal that’s strong, corrosion-resistant and highly versatile. It’s element number 28 on the periodic table, and while it might not get the limelight like gold or lithium, it’s crucial for making stainless steel and modern tech and energy systems tick.

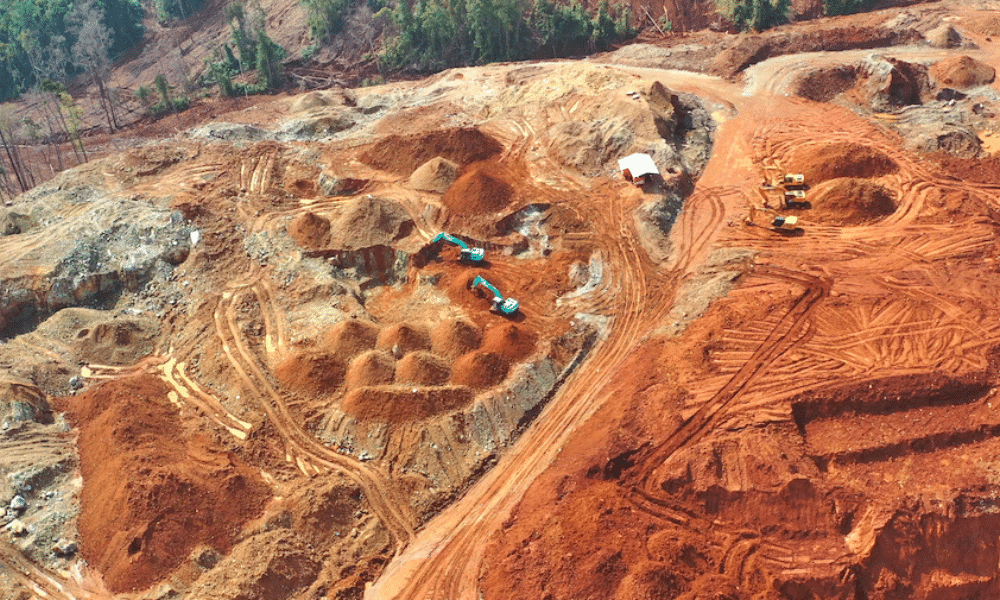

How is nickel mined?

Nickel usually comes from two types of deposits:

- Laterite ores: Found near the surface, especially in tropical areas like Indonesia and New Caledonia.

- Sulfide ores: Found deeper underground; think Canada, Russia, and parts of Australia (like WA’s Kambalda region).

The mining process depends on the ore type:

- Laterite: Typically mined via open-pit methods. The ore is then treated using high-pressure acid leaching (HPAL) or other chemical processes.

- Sulfide: Mined via underground techniques. The ore is crushed and processed through flotation and smelting.

It’s energy-intensive and can be dirty business, but cleaner tech is emerging, especially as demand spikes for green uses.

How is nickel used in manufacturing?

Nickel’s the quiet achiever in heaps of industries:

- Stainless steel: Over two-thirds of all nickel goes here. It adds strength, shine, and corrosion resistance.

- Batteries: Lithium-ion NCM (nickel-cobalt-manganese) and NCA (nickel-cobalt-aluminium) batteries used in approximately 30% of EVs and renewable energy storage. Nickel boosts energy density, which means longer-lasting power.

- Electronics and aerospace: Alloys with nickel handle extreme heat and pressure, perfect for jet engines and turbines.

- Coins and plating: It resists wear and keeps things looking sharp.

The rise of dirty nickel: What makes some nickel ‘dirty’?

The mining of nickel in Indonesia and the Philippines has come under intense scrutiny. It’s not about the metal itself, but how it’s mined and refined:

- High emissions: Some processes, especially laterite mining using coal-fired power, pump out a lot of carbon.

- Deforestation and land degradation: Open-cut mining in tropical areas can wipe out forests and ecosystems.

- Toxic waste: Some operations dump tailings into rivers or oceans, harming marine life.

- Poor worker conditions: Lack of regulation in some regions can mean unsafe or exploitative practices.

Is dirty nickel used in the manufacturing of electric vehicles, solar panels, battery storage, and other renewable tech?

Now, this is the million-dollar question. It is important to first understand the materials used in these technologies. We’ll deconstruct the EVs, solar panels, inverters, and home energy storage and have a look at some of the materials used to manufacture them:

| Material | EVs | Solar panels | Inverters | Home batteries |

| Lithium | Sometimes | No | No | Yes |

| Nickel | Sometimes | Sometimes | Sometimes | Sometimes |

| Cobalt | Sometimes | No | No | Sometimes |

| Graphite | Yes | No | No | Yes |

| Aluminium | Yes | Yes | Yes | Yes |

| Copper | Yes | Yes | Yes | Yes |

| Silicon | Sometimes | Yes | Yes | Sometimes |

| Silver | No | Yes | No | No |

| Rare earths | Sometimes | No | Yes | Sometimes |

| Iron | Yes | No | No | Yes |

| Steel | Yes | Sometimes | Sometimes | Yes |

| Plastic/Polymers | Yes | Yes | Yes | Yes |

| Glass | No | Yes | Sometimes | Sometimes |

| Lead | No | No | No | Sometimes (for older systems) |

Notes:

- Sometimes: Depends on specific product design or battery chemistry (e.g. LFP vs NCM batteries).

- Rare earths: include neodymium and dysprosium, mainly used in motors (EVs) and high-efficiency inverters.

- Silver: crucial for solar cells due to its conductivity.

- Graphite: the standard material for battery anodes in both EVs and home storage.

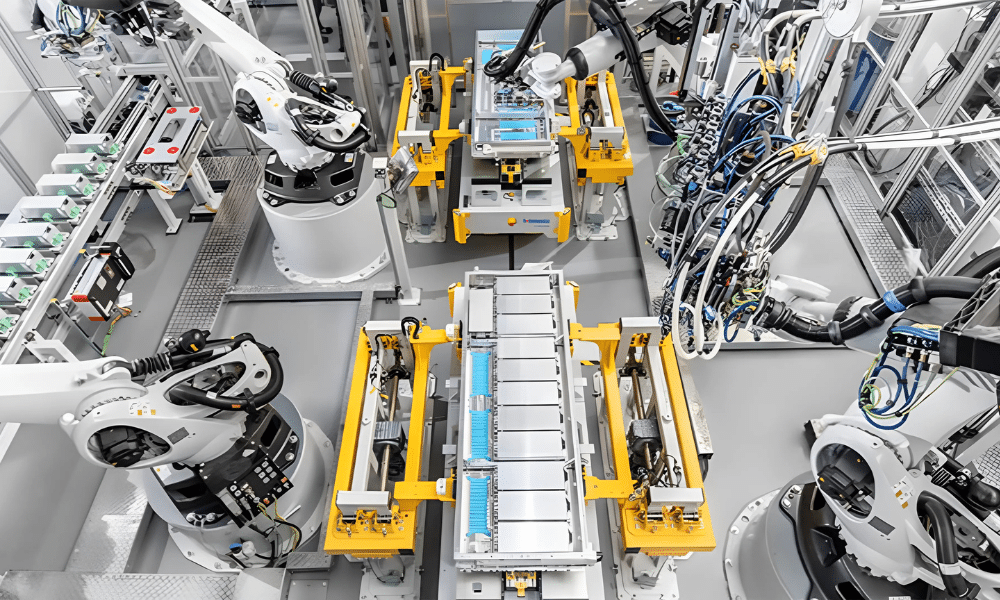

Electric vehicles and nickel

EVs are fast adopting battery chemistry that does not use nickel or cobalt. Lithium Iron Phosphate (LiFePO₄ or LFP) batteries are now being adopted across many EV manufacturers. BYD, one of the fastest-growing EV manufacturers, only uses LFP batteries in its vehicles. Tesla has also adopted the widespread use of LFP batteries with their Model Y and 3 vehicles.

For the EVs that do use NCM or NCA technology, they require specific levels of purity of the nickel for manufacturing.

| Battery type | Nickel grade required | Purity | Form commonly used |

| NCA | Class 1 | ≥99.8% pure nickel | Nickel sulphate |

| NCM | Class 1 | ≥99.8% pure nickel | Nickel sulphate |

The laterite nickel mined in Indonesia and the Philippines is almost entirely Class 2. The HPAL (high-pressure acid leach) processing method required to produce Class 1 nickel from these mines is seldom used due to the very high costs associated with this method.

Battery-grade nickel sulphate is usually produced from intermediate compounds like mixed hydroxide precipitate (MHP) or mixed sulphide precipitate (MSP), which are refined through energy- and chemically-intensive processes.

| Processing method | Nickel grade output | Purity | Typical use |

| High-Pressure Acid Leach (HPAL) | Class 1 | ≥99.8% | Batteries (after conversion to sulphate) |

| Pyrometallurgy (Ferronickel production) | Class 2 | ~20–40% nickel | Stainless steel and alloys |

| Nickel Pig Iron (NPI) | Class 2 | ~5–15% nickel | Mainly for stainless steel |

As such, most of the nickel derived from Indonesia and the Philippines is used in the manufacturing of stainless steel.

Solar panels and inverters

Nickel is seldom used in the manufacturing of solar panels or inverters. However, we’ll look at examples of where nickel is used:

Solar panels

Nickel is utilised in certain solar panel technologies, particularly in:

- Thin-film solar cells: Nickel can serve as a contact layer or be part of the cell’s structure.

- Nickel oxide (NiO): Employed as a hole transport layer in some photovoltaic cells, enhancing efficiency and stability.

While not as prevalent as materials like silicon or silver, nickel’s presence is notable in specific applications. Class 1 nickel would be required in both circumstances, so the likelihood of ‘dirty nickel’ being employed would be incredibly low.

Yingli Solar use copper to manufacture their solar panels and does not employ nickel. AIKO also do not use nickel in their solar panels.

Thomas Bywater, Country Director for AIKO Energy, stated:

“There is no nickel in the manufacturing of AIKO solar panels. There is one alloy of solder (used to join wires) on the market with nickel in it, but we are not using that and use other alloys.”

He continued,

“In terms of exposure for the wider industry, there is nickel in the 304 stainless bolts, fasteners, nuts + clips of the racking system and in batteries with NMC chemistry.

Some earlier batteries from Tesla and others had the NMC chemistry containing nickel; nowadays most popular options for fixed storage batteries in solar applications are LiFePO4 chemistry, and these batteries do not contain nickel, or cobalt, both of which, apart from having concern about deforestation in Indonesia, are limited and expensive metals.”

Inverters

Inverters may incorporate nickel in:

- Nickel-based batteries: Some inverters, especially in off-grid systems, use nickel-cadmium (NiCd) or nickel-iron (NiFe) batteries for energy storage.

- Electroplated components: Nickel plating can be applied to certain parts to enhance corrosion resistance and electrical conductivity.

Though not a primary material, nickel’s role in inverters is significant in specific contexts. Class 2 nickel could be present in old technology. Class 1 nickel would be required in all new inverters.

Home energy storage systems: Is dirty nickel used in home batteries?

The most common home battery systems in Australian households employ LiFePO₄ technology, which is void of nickel. However, we’ll look at the likelihood of nickel-based home batteries using dirty nickel.

| Battery Type | Nickel grade required | Purity | Typical use |

| NCM (Nickel-Cobalt-Manganese) | Class 1 | ≥99.8% | Home energy storage, EVs, high-performance |

| NCA (Nickel-Cobalt-Aluminium) | Class 1 | ≥99.8% | High-performance home storage and EVs |

| Nickel-Iron (NiFe) | Class 2 or lower | ~20–40% | Older or off-grid systems, less common |

The likelihood of your home battery housing dirty nickel is incredibly low.

Anker SOLIX, LAVO, BLUETTI, GoodWe, and FranklinWH employ LiFePO₄ in their batteries. Nickel may be used in the manufacturing of unit components, such as stainless steel. However, the manufacturers listed do not source or use dirty nickel to manufacture their products.

GoodWe further expanded:

“We give ‘green nickel’ an ethical name.” While the industry grapples with “dirty nickel”, GoodWe believes true sustainability means being “clean throughout the process.” The company stresses that “our responsibility is to ensure that the purchased nickel resources meet environmental and ethical standards throughout their entire life cycle.” With the upcoming launch of its Green Product Management System in August 2025, GoodWe is doubling down on transparency, echoing the EMRT 2.0 guide: “The significance of traceability is not only to identify risks, but also to promote the evolution of the entire supply chain towards a more responsible direction.”

You can read more about GoodWe and their environmental and ethical standards here.

Hydrogen production and nickel

Hydrogen production sometimes uses nickel mainly as a catalyst in key processes, especially steam methane reforming (SMR) and electrolysis. Though nickel’s role and required purity vary depending on the method.

In steam methane reforming (SMR)

Nickel is used as a catalyst to help convert natural gas (methane) into hydrogen. This is the most common method for producing grey or blue hydrogen. Class 2 nickel is often sufficient, as extremely high purity isn’t required for catalyst-grade nickel. The nickel is usually applied to a ceramic support material in small amounts.

In electrolysis (especially alkaline and PEM)

Nickel can be used as:

- An electrode material (especially in alkaline electrolysers)

- A substrate for catalysts

- Electrolysers need higher-purity materials, especially for performance and durability.

In this case:

- Class 1 nickel or refined nickel alloys are preferred for long-term stability and conductivity.

- However, the exact grade depends on the manufacturer and type of electrolyser (e.g. alkaline, PEM, solid oxide).

This could mean that these processes incorporate dirty nickel in their hydrogen production.

LAVO do not use nickel for hydrogen storage. Their metal alloy components are all nickel-free.

The verdict

While dirty nickel remains an economic, environmental, and social issue, it is not commonly used or found in the renewable energy technology manufactured in China and similar manufacturing countries or used in Australia. Due to its purity levels, around 70% of all the dirty nickel produced in Indonesia and the Philippines is used to manufacture stainless steel. This could mean that your shower head, kitchen sink, or even the utensils you eat with are made using dirty nickel.

The dirty nickel debate shines a spotlight on how nickel is mined and processed around the world. Whether it ends up in renewable energy tech, household appliances, or even the phone in your hand, it pays to know where these materials come from. Convenience today shouldn’t come at the cost of communities or the planet tomorrow.