Researchers at Oregon State University (OSU) have developed a process that harvests the power of the sun to produce materials needed to make solar cells.

One of the still prevalent myths regarding solar power is it takes more energy to create a solar panel than what that panel will produce over its serviceable life. The truth is the energy payback time is generally just a couple of years – and in the case of modules such as REC solar panels; as little as 12 months.

Some manufacturers also partially power their facilities with solar panels, or purchase electricity from renewable sources.

The OSU researchers have taken things a step further to reduce the embodied energy in solar modules.

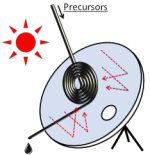

The process involves the use of continuous flow microreactor to produce nanoparticle inks used for printed solar cells. Sunlight is focused on the solar microreactor in a way that allows for precise control of temperature. In their experiments the light used was artificial, but the process could be executed with direct sunlight.

The process is not only more eco-friendly, but more economical and faster.

“Our system can synthesize solar energy materials in minutes compared to other processes that might take 30 minutes to two hours,” said Chih-Hung Chang, a professor of chemical engineering at Oregon State University and lead author of an associated paper on the technology.

“It could produce solar energy materials anywhere there’s an adequate solar resource, and in this chemical manufacturing process, there would be zero energy impact.”

Professor Chang says the process could operate around the clock with the addition of molten salt energy storage – a technology already in commercial use at some solar farms.

In their experiments, the solar materials were created with copper indium diselenide, but Professor Chang says the use of compounds such as copper zinc tin sulfide may be possible; which would further cut costs.

The team’s findings were recently published in RSC Advances, a journal of the Royal Society of Chemistry.