In the past few years, solar energy panel technology has advanced to a new level, and with new technology comes unique inventiveness. Numerous solar panels are used in multiple applications, so there isn’t necessarily a “one-size-fits-all” variety.

Solar cells and PV panels at a glance

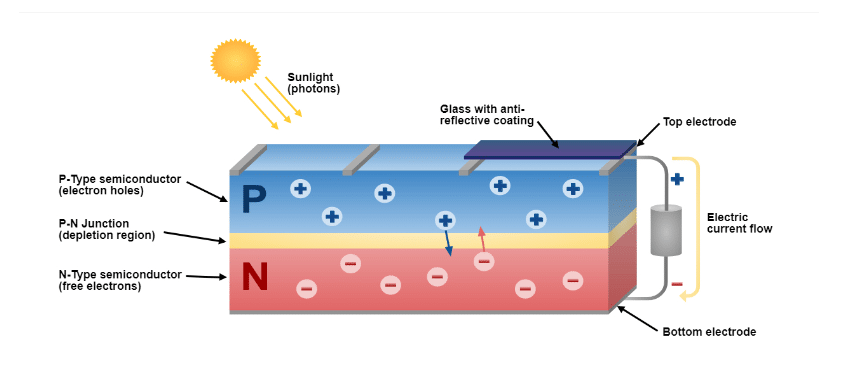

The conversion of light (photons) into electricity (voltage), known as the photovoltaic effect, is the basis for photovoltaics, abbreviated as PV. Solar PV or photovoltaic systems are built as investments that, if paid for, will give their homeowner access to free electricity throughout the day, saving energy bills.

Additionally, installing solar photovoltaic systems generates electricity from the sunlight without emitting glasshouse gases. Therefore, technologies with higher excellent energy efficiency ratings that use less energy to make the same effort are vital to reducing the country’s greenhouse emissions. A PV cell’s efficiency can be calculated as the electrical power it produces to the energy from the light shining on it. This ratio shows how well the cell converts energy from one form to another. The qualities of the available light (such as its intensity and wavelengths) and the number of cell performance factors determine how much power PV cells generate.

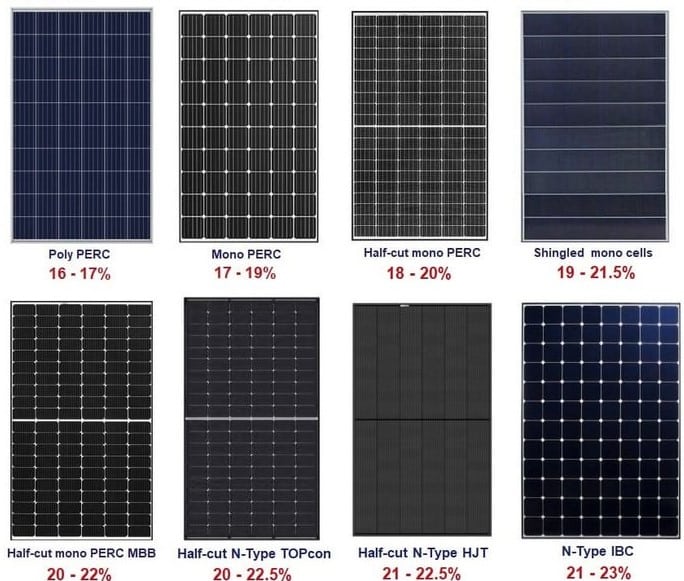

Source&Image: Clean Energy Reviews

Several photovoltaic cells have been enclosed for safety and to allow the voltage produced by each solar cell to be combined up a solar panel, commonly referred to as a PV panel. Check out this link for advice on picking the best solar panels, and this page has further information on residential solar panel sizing.

Energy Matters has a nationwide network of trusted local installers ready to provide you with up to 3 Free Solar Quotes. Get your free quotes today!

How old are solar panels?

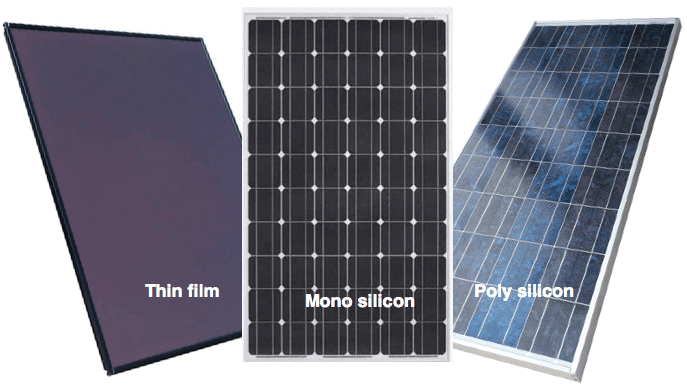

Since the 1950s, crystalline silicon has been the only technology available in PV cells. However, new technologies have rivalled silicon in the last ten years. In the 2000s, thin-film technology made strides and nearly overtook silicon as the dominant technology. The cost of silicon cells fell sharply due to China’s rise in mass production.

On the back of the new advancements, other technologies, such as poly and monocrystalline PERC cells, are now getting on board.

We are already witnessing very high efficiency (up to 23%), and the cost is steadily declining for monocrystalline silicon technology.

Different types of solar panels and solar cells

New advanced solar PV technologies

- Passivated Emitter and Rear Cell (PERC) – Mono PERC and Poly PERC

- Half-Cut Cell Solar Panels

- Bifacial Solar Panels

- Shingled Cell Solar Panels

- N-Type Solar Cell Technology

- P-Type Solar Cell Technology

Traditional solar panels

- Mono-crystalline Silicon – also known as single-crystal silicon

- Poly-crystalline Silicon – also known as multi-crystal silicon

- Thin Film – Amorphous silicon (a-Si), Cadmium Telluride (CdTe), Copper Indium Gallium Selenide (CIGS)

Passivated Emitter and Rear Cell (PERC)

PERC solar panels have improved the traditional monocrystalline and polycrystalline cells. This relatively new method adds a passivation layer to the rear surface of the cell, which enhances efficiency in numerous ways. It increases efficiency by allowing electrons to move more freely and making the back of solar cells more reflective.

PERC panels are perfect for locations with limited space because they increase solar energy collection and reduce physical footprint. Due to the additional materials required, they are only marginally more expensive to create than traditional panels. However, they may still be made using the same technology and have a lower average cost per watt because of their efficiency.

Mono PERC cells

Since monocrystalline solar cells are made from a single silicon sheet, they are more effective than polycrystalline solar panels. PERC layers can be applied to boost efficiency rates further.

Poly PERC cells

Polycrystalline PERC cells, in contrast to conventional monocrystalline cells, are created utilising a mixture of silicon shards. Although the efficiency of this mixture is lower, polycrystalline cells are less expensive to produce.

Half-Cut Cell Solar Panels

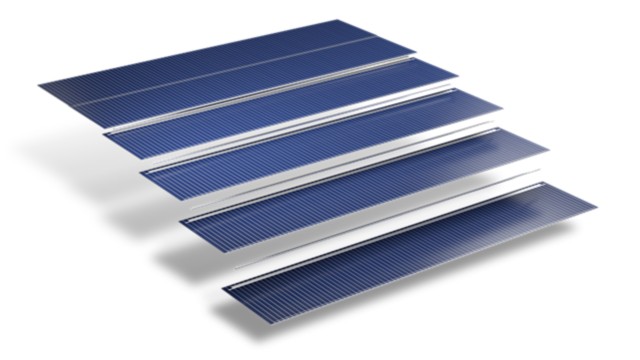

As the name suggests, half-cut solar panels have solar cells divided in half. Technology for half-cut solar cells is based on and made of the same materials and components as traditional crystalline silicon (c-Si) solar cells.

The half-cut solar cell uses the same technology as conventional ones. Still, they differ due to a redesign that aims to increase performance and decrease electrical losses from traditional panels.

Check our page about the stand-out award-winning half-cut cell technology of REC solar panels.

Bifacial Solar Panels

Bifacial solar panels can absorb solar energy from both sides of the panel. Some bifacial module manufacturers claim that the backside reflection of light alone can enhance power production by 30%. Bifacial solar panels function best when placed next to highly reflecting surfaces—for instance, glass swimming pools, sand, stone, or snowy surroundings.

Shingled Cell Solar Panels

Solar cells used in shingled panels are divided into five or six strips. They are then placed on top of one another, much like roof shingles. These overlays connect electrically and are attached using an electrically conductive adhesive to improve conductivity and flexibility.

These solar panels don’t require busbars and don’t have spaces between the cells. They also produce more power per square metre. The cells receive more sunshine exposure, allowing them to make more electricity than traditional solar panels.

N-type solar cell vs P-type solar cell

The silicone base of a P-type cell contains boron atoms infused into it to produce an overall positive charge (thus the “P” in the name). Phosphorus, a component of an N-type, is infused into the top silicon layer of the wafer or cell to form a positive-to-negative junction for electrical current flow.

Fundamentally, N-type cells are the P-type cell’s total opposite. N-type has a silicon base induced with phosphorus creating an overall negative charge. For the p-n junction to occur, boron (P-type) is injected into the top layer of N-type silicon cells.

Due to benefits, manufacturers are now employing N-type cells. They are resistant to boron-oxygen defects, causing P-type ones to function less efficiently and with lower purity. N-type cells are more effective and immune to light-induced deterioration (LID). N-type cells have a 1%–3% performance loss during the first few hours of exposure to the sun.

Monocrystalline silicon panels

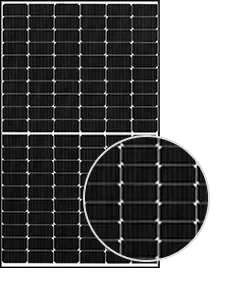

Monocrystalline solar cells are usually dark black in appearance. The corner in the cell is generally absent because of the production of monocrystalline silicon.

The crystal is formed into an ingot shape, which is a cylindrical log and is subsequently divided into thin discs to create octagons. The edges of each disc are sliced.

Polycrystalline solar panels

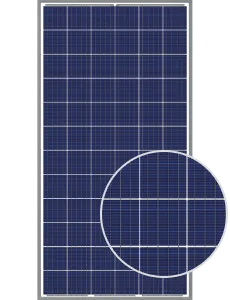

Polycrystalline solar panels are frequently viewed as a more cost-effective option, especially for homeowners, because of their 15-17% efficiency.

They are created by melting several smaller silicon crystals together and then recrystallising. They are produced more quickly and with less waste than monocrystalline panels.

Thin Film solar panels

Despite being the least expensive photovoltaic option, thin-film technology is less popular than crystalline cells and modules. Thin-film technology has a substantially shorter lifespan than crystalline technology because thin films are the least efficient photovoltaic choice. Additionally, thin-film technology requires much more space than crystalline panels due to its low efficiency in producing the same energy.

Amorphous silicon (a-Si)

Amorphous silicon is non-crystalline silicon popularly utilised in consumer electronics and calculators that need a little current flowing at a low voltage. Amorphous silicon has a light absorption rate of over 40 times greater than crystalline silicon among the many types of photovoltaic cells on the market. This benefit requires a considerably thinner layer of amorphous silicon material, which lowers the cost and price of manufacturing thin film PV cells.

Cadmium Telluride (CdTe)

Among all solar panel varieties, CdTe has the lowest carbon footprint, water need, and energy payback period. It also shares the same low cost advantage as polycrystalline cells. Cadmium is hazardous, thus, recycling it costs more than other materials.

Copper Indium Gallium Selenide (CIGS)

Thin layers of copper, indium, gallium, and selenium are put on a glass or plastic backing to create CIGS panels. Although not as effective as crystalline silicon panels, the combination of these components yields the highest efficiency among thin-panel types.