The most common solar PV technology, crystalline silicon (c-Si) cells, is frequently mentioned when discussing solar energy materials. Thin film solar cells are a fantastic alternative that many people are unaware of for converting visible light into usable power output.

On This Page

In the second generation of crystalline silicon (c-Si) panels, thin film solar cells are created by depositing one or more layers of thin photovoltaic materials on top of various elements like glass, metal, plastic, or a mix of each. Compared to first-generation c-Si technology, the thin layers enable more flexible and lightweight applications.

What are thin film solar panels?

Solar cells that create thin film solar panels include light-absorbing layers about 350 times thinner than those in a typical silicon solar panel. Thin film solar cells are the lightest PV cells with strong durability because of their narrow shape and the effective semiconductor incorporated into their cells.

Researchers at the Institute of Energy Conversion at the University of Delaware in the United States first developed thin film solar panels in the 1970s. The thin film photovoltaic market was developing at an astounding level and was expected to continue increasing as technology continued to advance in the early twenty-first century.

The kind of surface used in producing thin film solar panels is a defining characteristic. Four different types of films are utilised, including

Cadmium telluride (CdTe) thin film solar panels

With a 50% market share, this type of film is most frequently utilised in producing thin film solar panels. Because they contain a significant amount of hazardous metal cadmium, employing thin film solar panels with a CdTe has disadvantages. Although tested up to 18.7%, these panels have an efficiency range of 9–11%.

One of their most interesting features is the capacity of CdTe panels to absorb sunlight at wavelengths close to ideal or at shorter wavelengths than are feasible with conventional silicon solar cells. Higher energy and easier electricity conversion are associated with shorter wavelengths. Additionally, cadmium telluride panels are less expensive to produce and install than other solar panels.

CdTe solar cells, however, have a few downsides, including

- Rarity: Because it is so hard to obtain, tellurium is difficult to create in large quantities.

- Toxicity: Due to its high toxicity, cadmium must be handled with extreme care.

Amorphous silicon (a-Si) thin film solar panels

Since amorphous silicon (a-Si) solar is the most established type of thin film PV technology. It is also the oldest. This non-toxic panel applies a thin silicon layer to the glass, plastic, or metal base via chemical vapour deposition.

Amorphous silicon has resulted in solar cells that are less efficient and suited for small-scale applications. However, the A-Si thin film solar panels have greater efficiency rates than CdTe. This kind of thin film solar panel is more popular than CdTe panels. Compared to CdTe and CIGS, they are more durable and less hazardous.

Copper indium gallium selenide (CIGS) thin film solar panels

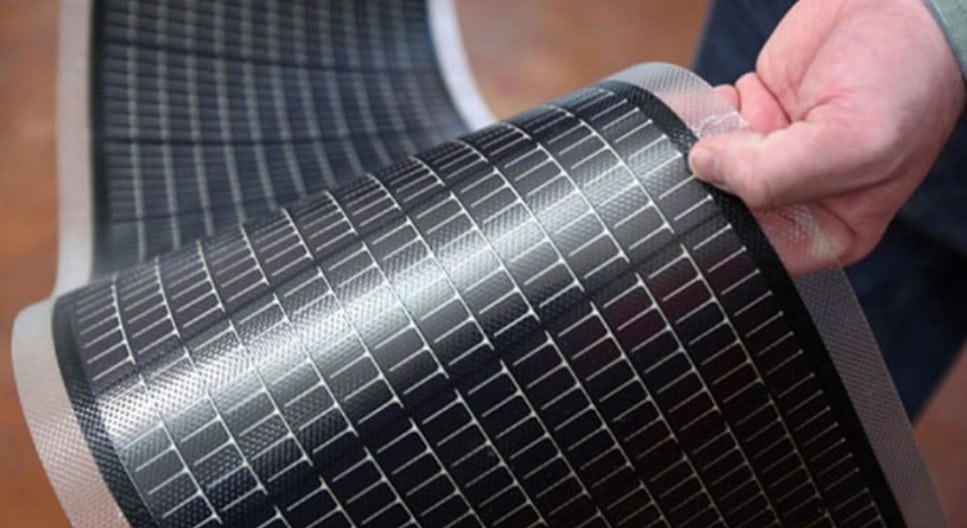

Copper gallium indium diselenide is placed between conductive layers to create CIGS solar cells. This substance is placed on top of several layers, including glass, plastic, steel, and aluminium. The tiny layers of some CIGS panel types’ flexible backings enable full-panel flexibility.

The tiny layers are more versatile than conventional solar technology thanks to their adaptable backings. CIGS thin film is a highly efficient technology with particular efficiencies exceeding 20% in lab tests. The poisonous substance contained in cadmium telluride (CdTe) panels, cadmium, is unfortunately also used in a lot of CIGS panels.

Zinc oxides, which are more environmentally friendly, have replaced the chemical in certain modern CIGS cells. In general, the price tag is a significant drawback. Due to their high production costs, CIGS solar panels still struggle to compete with CdTe or silicon solar panels.

Organic Photovoltaic (OPV) Solar Panels

Organic photovoltaic (OPV) panels generate power using conductive organic polymers or tiny organic molecules. Many layers of thin organic vapour or solutions are positioned between two electrodes in these photovoltaic cells to carry an electrical current.

Because plenty of organic components are used, the method reduces overall cost from production to market. OPV panels can be a variety of colours, even translucent, thanks to the variation in absorbers, making them the go-to solar module for any aesthetic requirements. Despite the hype surrounding its aesthetic potential, OPV solar has efficiency issues.

The building-integrated photovoltaic (BIPV) market is dominated by OPV cells. It is possible to use many absorber types in an organic cell, allowing OPV devices to come in various hues and be transparent! This aesthetic benefit makes OPV a common choice for innovative BIPV applications. The materials that businesses require to create organic solar cells are readily available, which results in low manufacturing costs and low market prices.

The lifespan of OPV technology is another drawback; it is less durable than conventional panels and other thin film alternatives. Cell breakdown that doesn’t happen in inorganic modules is a constant battle for organic photovoltaic devices.

Are you tired of being the last to know about renewable energy updates? Did you miss out on a state rebate or incentive? Looking to find out more about how you can save on your utility bills? Subscribe to Energy Matters’ weekly newsletter and keep updated with Australian and international news, incentives, and offers.

How are thin film solar cells made?

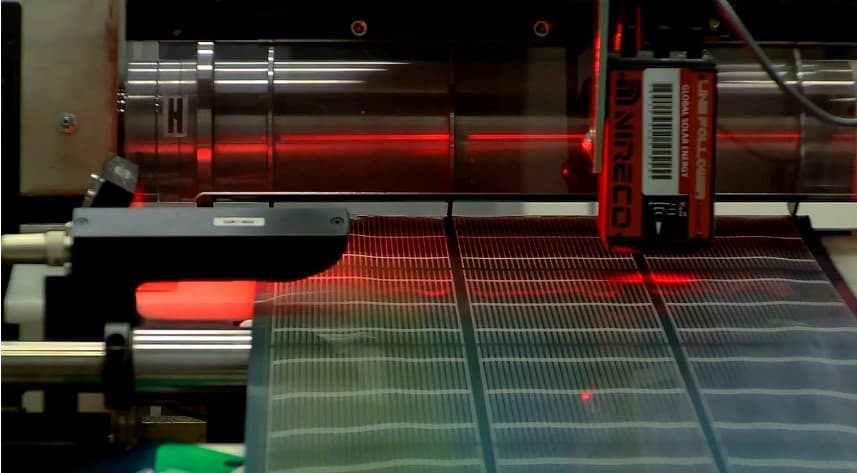

Image: Wikimedia Commons, Stanford ENERGY, Video by Mark Shwartz

There are three major components to any thin film solar panel:

Photovoltaic material

The primary semiconducting component, CdTe, a-Si, or CGIS, turns sunlight into energy.

Conductive sheet

A layer of conductive material, such as aluminium, is required to improve conductivity and stop electricity loss.

Protective layer

A thin layer of high-quality glass or plastic is added to the top of the system to increase durability and shield it from the environment to increase the lifespan of the solar module.

Advantages and disadvantages of thin film solar panels

Depending on your demands and objectives, thin film solar panels have advantages and limitations, just like any other solar technology. Consider the following factors while determining whether thin film solar panels are the best option for you.

Advantages of thin film solar panels:

- Easy and inexpensive installation

- Great for portable applications (RVs, buses, boats)

- Lightweight

- Faster payback time than conventional panels

- Their power output is less affected by high temperatures

Image: Hanergy’s MiaSole

Disadvantages of thin film solar panels:

- Use a more toxic manufacturing process that may contain cadmium – a probable carcinogenic

- Lower efficiency than conventional panels

- More roof space is needed for the same energy capacity

- Limited availability

- Shorter lifespan than traditional panel

Energy Matters can connect you with our trusted local installers, who will provide up to 3 FREE solar quotes for your home and business solar energy system. Complete our quick quiz and begin your solar journey today!