Australia’s only solar panel manufacturer, Tindo Solar in South Australia, has invested millions into a new factory and production line as it hopes to produce enough panels to meet the growing demand for Australian-made panels. Twenty years ago, Australia had a burgeoning solar manufacturing industry, but this was short-lived. China now accounts for roughly 70% of global solar panel production, compared to Australia’s dismal 0.3% share. However, with news of a China supply crunch, could local manufacturing provide a lucrative opportunity and a long-term solution for supply security?

China solar boom an “Australian initiative”

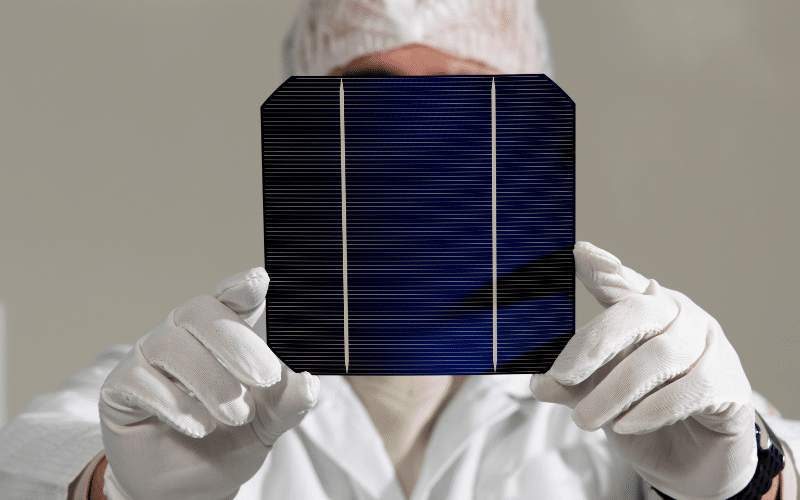

Every day of the year, Australia installs about 1,000 rooftop solar systems; representing billions of dollars spent on silicon, glass and a little bit of metal. Given the immense local demand and availability of raw materials required to produce panels, why is Australia such a non-player in the solar game?

Back in the late 1990’s, the BP Solar factory in Homebush, Sydney, was in full swing. At the time it was the largest solar factory in the southern hemisphere, serving the domestic Australian market and exporting to South-East Asia.

Australia was also at the leading-edge of solar PV research, with the University of New South Wales (UNSW) photovoltaic research team breaking records for solar cell efficiency.

A few short years later, the factory was shut and UNSW’s brightest minds in solar photovoltaics had left the country to set up China’s first solar PV factories.

Where did we lose our way? As with most ventures gone awry, it largely boils down to simple economics.

Shi Zhengrong, a foreign-exchange scholar who was part of UNSW’s photovoltaic research team, decided to take a punt and move back to China to found a solar manufacturing company, Suntech.

At the time, China produced no solar panels.

“I’ve been asked many times, why did I start the business in China, not Australia?” Dr Shi says.

“When I was in Australia, I was just a scholar and a student. I really didn’t have much confidence in running a business over there. Also the cost of labour in Australia is fairly high.”

The punt paid off. In 2005, Suntech listed on the New York Stock Exchange and raised $US420 million, making Dr Shi a billionaire.

This decision had a snow-ball effect, with other UNSW graduates following in Dr Shi’s footsteps and moving to China to start their own solar factories at a much cheaper cost than Australia.

With US investment soon following, it wasn’t long before China grew into the solar superpower it is today, leaving local manufacturing all but wiped out.

Covid-19 drives locally-manufactured panel sales

The world’s economy has experienced a significant shake-up due to Covid-19 and the solar panel industry is no exception. Speaking to The Advertiser, Tindo’s CEO Shayne Jaenisch said the advent of Covid-19 has catalysed a boost in consumer demand for Australian made products including solar panels.

“We had consumers contacting us from all over Australia, saying that they want to buy Australian-made,” he said. “We’ve had record sales.”

Mr Jaenisch sees this as a lucrative opportunity for local manufacturing, and hopes to build a network of local suppliers so that every component of the solar panel system is manufactured in Australia.

“Covid has taught us all a valuable lesson, that we are too reliant on overseas imports, especially from China,” he said.”

Looming solar panel supply crunch

Australia is currently facing a solar panel supply crunch, with numerous factors at play. These include shortages in solar panel’s key raw materials (i.e. polysilicon, steel, aluminium and copper), high shipping costs, and China’s energy crisis, which is forcing panel manufacturers to halt production to curb emissions.

This shortage has already driven up prices significantly in the US and parts of Asia, and is starting to have the same effect in Australia.

With growing demand for Aussie-made panels and the looming China supply crisis, we may be looking at the perfect opportunity for a resurgence in local panel manufacturing.

“We want to bring back more manufacturing, not just solar panels but the upstream manufacturing of everything from our glass to our cells to our frame”, said Mr Jaenisch.

“We’re pushing for the upstream manufacturing to come back, so that we can have sovereignty and so that we have the ability to employ more Australians and be less reliant on overseas.

“We’ve got all the raw materials here, we should be making everything that goes into a solar panel.”

We are already starting to see some activity in local solar manufacturing. Just last week, Fortescue Metals, one of Australia’s largest mining companies, announced they are undertaking a feasibility study into building an Australian factory for a unique photovoltaic technology.

Beat the panel price-hike

With summer around the corner and the threat of price increases across the board, there’s no time like the present to invest in solar.

Assisting over 30,000 Australians in their transition to clean energy, Energy Matters can guide you toward a solar and/or battery storage solution that fits your lifestyle and budget. Receive up to 3, obligation-free solar quotes from our trusted network of accredited solar installers. It’s fast, free and takes the hassle out of shopping around.