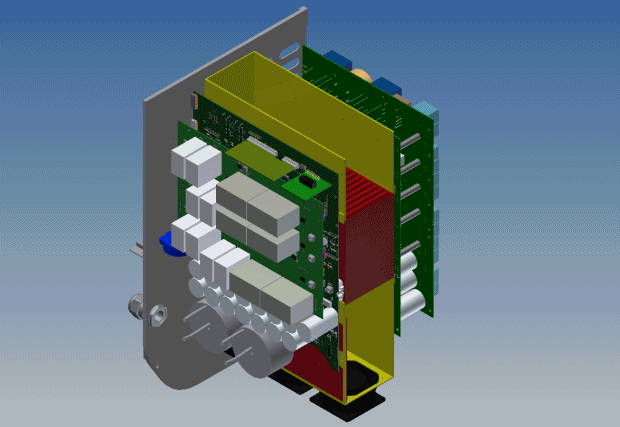

A three year project to develop a concept for the next generation of solar PV inverters has claimed success, resulting in a more efficient and cost effective design.

The project, which commenced in 2014, was led by researchers at the Fraunhofer Institute for Solar Energy Systems ISE in collaboration with leading inverter manufacturer SMA, Fraunhofer Institute for Manufacturing and Applied Materials Research IFAM and Phoenix Contact GmbH & Co. KG.

The aim of the project, dubbed PV Pack, was to optimize cooling, packaging and assembly technologies for solar inverters in the 30 to 70 kW power range.

A cost analysis of mechanical and electromechanical components of an inverter found these elements account for up to 70 percent of overall costs for current solar inverters.

“One way of cutting costs is to optimize the technologies of the components used in lower power classes in such a way that devices with more power can developed,” said Fraunhofer ISE’s Sebastian Franz.

An important area of focus was the “hot core” of the inverter, which enables losses associated with semiconductor, manifesting as heat, to be channeled away via a heat sink on multiple sides.

The researchers found by decoupling the cooling element from the housing, the maximum temperature could be increased by 30% (from 80 to 105 °C). Furthermore, the use of sintered materials allowed for a dramatic reduction in material use.

By using silicon carbide semiconductors (SiC), which offer increased switching frequency, passive element size was reduced – resulting in increasing power density and a further reduction in material use.

The inverter concept features different temperature zones, with the cooler zones able to be utilised for cost-efficient components with lower temperature requirements.

Through utilising modified readily-available cost-effective technologies and combining them in an optimal way, the maximum efficiency for a 70kW inverter concept developed during the project was 98.8%. The total weight of the inverter, including housing, was 58.5 kg; with it requiring 110 liters of installation space.

“At 1200 W/kg, the power density greatly exceeds devices available on the market,” said Mr. Franz.

The two-stage inverter platform incorporates five MPP tracker and three neutral-point-clamped inverter bridges.

As to any cost reduction that could be achieved, that wasn’t clear from the report.

Further information on the PV Pack project results can be viewed here.

Related: